Good day, I am looking at the parameters and it seems I haven’t figured out all the capabilities of the controller. James, please help me!! Let’s go through an example to understand the algorithm of the controller and its capabilities.

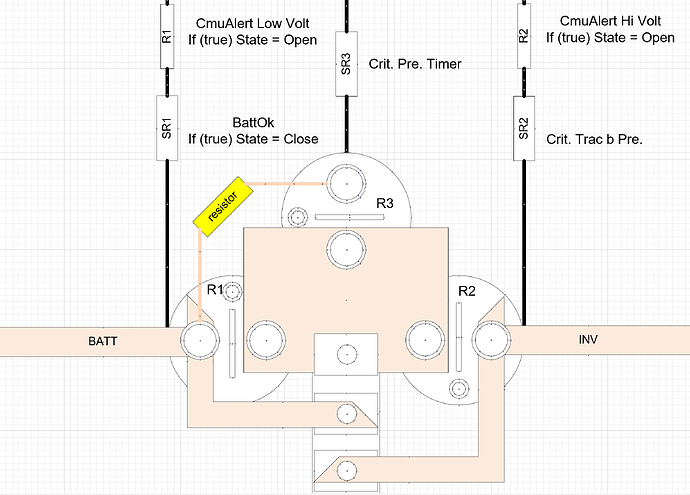

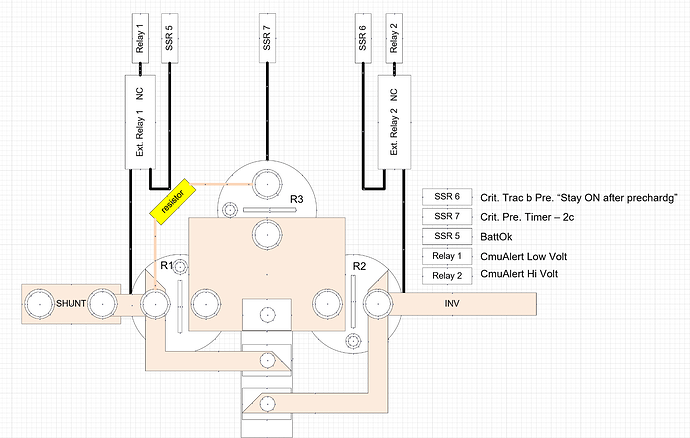

Here is an example of the control actions after the BMS (Battery Management System) is turned on:

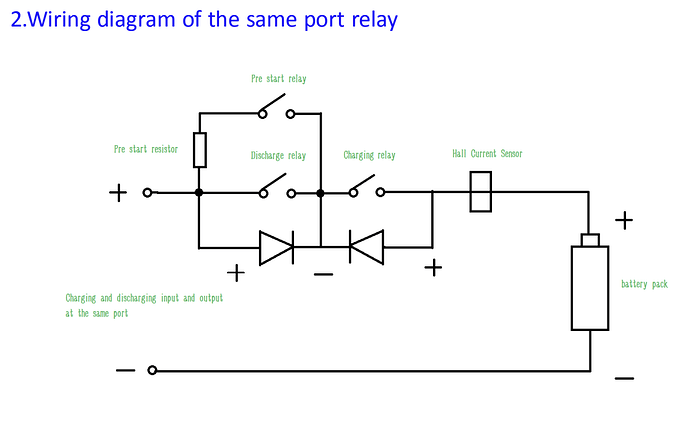

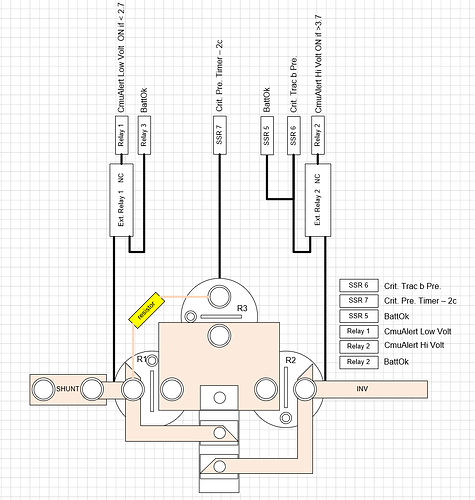

Precharge Stage

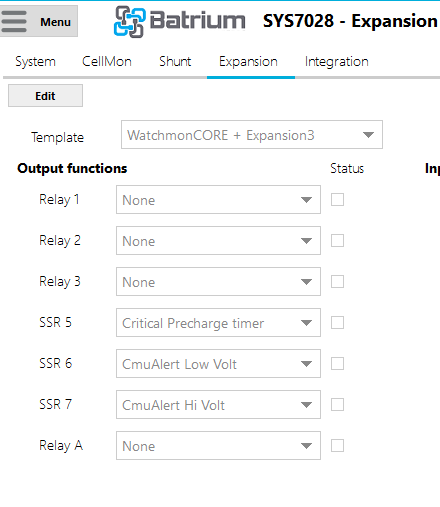

SSR6 = ON to start the precharge process, “allowing battery charging”;

SSR7 = ON for a duration of (Precharge Time 2s) “allowing battery discharge through the resistor”;

SSR5 = ON while the time hasn’t expired - 2s for precharge;

SSR7 = OFF upon timer expiration of 2s. Precharge stage completed;

Normal Operation Mode of BMS

SSR6 = ON - allowing battery charging;

SSR5 = ON - allowing battery discharge;

SSR7 = OFF;

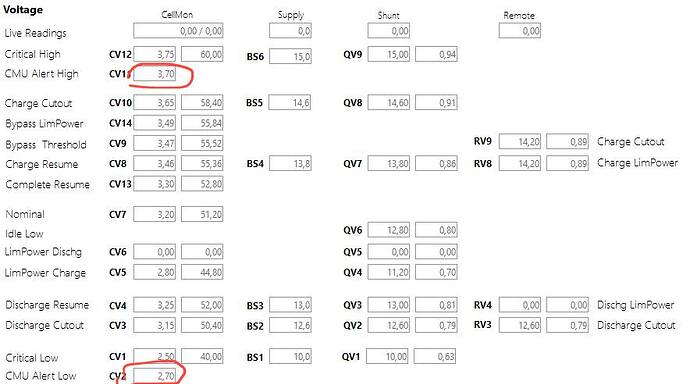

If the cell status value falls within the range: Critical->Hi Cell Volt = 3.75 and Charging->Cell Hi Cutout = 3.65v, the following relay actions occur:

SSR6 = OFF - prohibiting battery charging;

SSR5 = ON - allowing battery discharge;

SSR7 = OFF;

The transition from this mode to normal mode occurs by switching relay SSR6 = ON.

If the cell status value falls within the range: Critical->Low Cell Volt = 2.5 and Discharging->Cell Low Cutout = 3.15v, the following relay actions occur:

SSR6 = ON - allowing battery charging;

SSR5 = OFF - prohibiting battery discharge;

SSR7 = OFF;

The transition from this mode to normal mode is carried out through the precharge procedure with the following actions:

SSR6 = ON - maintaining the previous state of allowing battery charging;

SSR7 = ON for a duration of (Precharge Time 2s) “allowing battery discharge through the resistor”;

SSR5 = ON while the time hasn’t expired - 2s for precharge;

SSR7 = OFF upon timer expiration of 2s;

If the variable BattOK = 0, the emergency shutdown procedure is initiated through Stop Charge/Discharge Prior:

- Set relay SSR7 to the closed state for precharge, duration (Precharge Time 2s);

- Open relay SSR5;

- Open relay SSR7;

- Open relay SSR6.

Without manual intervention, the battery will not return to normal mode.

tell me how to change the values of the parameters CV11 to 3.7, CV2 to 2,75.

Presumably this will allow using the triggers CmuAlert Low Vlot and CmuAlert Hi Vlot as I want and this will happen before the BMS switches to emergency mode.