New Build system. Looking for good ideas on how to use two shunts most effectively.

I have a Victron SmartShunt and a Batrium Shunt, Cerbo GX and touch 70, 4 x 48V battery banks with Cellmate K9’s. VIctron Quattro and various Orion DC/DC Offtakes. How can I use these two shunts to get the most valuable information?

Maybe split the 48V DC Lynx distribution into two buses: Feeds to Quattro, Feeds to DC?

cheers for you ideas.

Hi Phyllis,

Our BMS only has the ability to talk to one shunt (for now!). My understanding is that Victron can likely see multiple shunts, but only select one (likely ours) as the battery monitor.

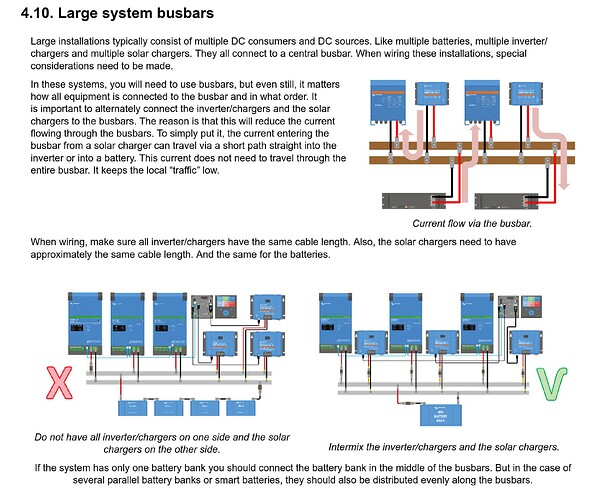

Your suggestion for measuring power flow to different devices is interesting, but might go against Victrons recommendation to space inverters, chargers, and batteries out:

Specifically this extract:

Phyllys,

I have a system that uses the same components and also has a different mfg. of my inverter for a/c power out. My system has the charging circuits in the middle of the DC and this allows me to put a Victron shunt inline with the inverters showing power use through the cerbo gx, and between the chargers and the batteries using the batrium shunt showing battery charge/discharge rates and voltage. Now for the fun. you hook up the discrete outputs from the batrium to the discrete inputs on the cerbo. now you have the ability to program relay out on the batrium for charge allowed, discharge allowed, heat and cooling required, bypass fan required, battery in fault etc with a output board. Not the cherry on top, comms through the bms-can from batrium to Cerbo. now the bms can control or not the solar charge controller, send shunt info as state of charge on the battery and DC voltage at the shunt. I added 2 more Victron D/C shunts direct connect to the cerbo breaking out he solar vs the A/C battery charge. All the information you need is now at your fingertips. find a Guru on the cerbo view programming and output to a monitor. now you display all power being used and how much is solar,A/C charger, and Battery. What the charge/discharge rates, are for every area of interest. what the batters charge status is, charging is allowed, discharging, is allowed, heating/cooling, bypass fan requirements, battery condition etc. Shows the control values if the batrium is in charge if the solar chargers and if they are following instructions. This is what realtime control can and does look like. through the cerbo you can be alerted to any of this through text and or email and if you sail tie to into Starlink and now have interplanetary control of. your power system! Cool Stuff to have a think about.

Many thanks for this. Very clever. Do you have one Shunt set as “the truth”? or is this all calculated from multiple shunts? Is there a reason you went Victron Shunts?

I am using two shunts, too. And my setup is therefore also different from the ones explained in the Victron Wiring Unlimited.

I split the Lynx busbar into three parts with the shunts between them. Left Lynx busbar has connection to all battery banks. Its negative bar passes then the Batrium shunt to measure all current going to or from the batteries. My middle busbar connects all inverters and solar chargers. My right busbar connects all DC loads and the Victron shunt sits between middle and right busbar measuring all DC loads.

This setup gives me very accurate information about all energy flowing in the system, from where it flows and to where it flows. I would recommend this setup to everybody else.

the victron shunts integrate easily with the cerbo gx and can show up in the widgets with the correct labeling. There is truth when 2 or more systems agree. You want 1 system, in your case the cerbo gx to react to the data. It sees all the systems data necessary for safety and responds as programmed. There is only 1 chef in the kitchen and he needs all the data to decide the course of action to be taken.

Also in regards to best practice shown for victron wiring, this is using recommended minimum wire size for the load. My full load is 1000 amps and my solid copper buss bars are rated for 2000 amps. This keeps all my voltage readings the same regardless of load and the readings stay calibrated without issue. The only issue is cost, but the safety and reliability lets me sleep at night. If you correctly size per victron you need to follow best practice or lose you mind trying to get readings to match under load and unloaded